Wear Loss Evaluation of Silicon Nitride-Hexagonal Boron Nitride Composite using Taguchi Method

Juniper Publishers

Wear Loss Evaluation of Silicon Nitride-Hexagonal

Abstract

Objective: Research in the field of bio-tribology is trying to evaluate biomaterials with minimum wear. Recently Silicon nitride (Si3N4) is suggested as an alternative for hip/knee joint replacement. With the addition of hexagonal boron nitride (hBN) in Si3N4, its wear properties can be improved.

Methods/Analysis: In this paper, an attempt has been made to evaluate the sliding wear behavior of Si3N4-hBN composite against alumina and steel (ASTM 316L) so as to minimize its wear loss. An attempt has been made to find the effect of hBN addition on wear performance of Si3N4. The experiments were conducted according to Design of Experiments (DoE)-Taguchi method to evaluate the effect hBN addition.

Findings: Taguchi analysis presents 15N load and 8% volume of hBN against alumina, while 15N load and 12% volume of hBN against steel is optimum to minimize wear loss of Si3N4.

Keywords: Design of experiments (DoE); Taguchi method; Silicon nitride (Si3N4); Hexagonal boron nitride (hBN); Alumina; Steel

Introduction

Biomaterials in body environment are expected to work satisfactorily, where the pH value of body fluid varies from 1 to 9. Friction, wear, and lubrication of artificial joints are an important consideration to optimise the performance of these man-made joints to improve its function and life. The first metal-on-metal (CoCr-CoCr) total hip replacement (THR) was unsatisfactory because of high friction forces and high rate of wear. Titanium alloys and stainless steel are frequently used in THR. The main risk with metal alloy implants is the release of metal ions due to wear and which creates an adverse effect like aseptic loosening. Therefore metal-on-UHMWPE bearing became advantages or preferable to the metal-on-metal system. Ceramic bearings were first introduced as alternatives to polyethylene (PE) bearings in THR about a decade after Sir John Charnley introduced the first durable THR with a metal-PE articulation. In 1965, the first Al2O3 material dedicated for hip joint was patented, and pioneering application of bio-ceramic was replacing traditional metallic femoral heads of hip prostheses using high density and pure alumina. The Al2O3 and ZrO2 like oxide have a lengthy history in the field of hip and knee joint replacement providing a tougher bearing surface with low wear rate. Initially, in the engineering field, Si3N4 was proposed as a substitute for conventional materials in extreme operating conditions, due to its hardness, excellent chemical and stability under a broad range of temperature, low density, low thermal expansion, high specific stiffness, corrosion resistance, high elastic modulus and low friction properties [1]. Biocompatibility and material properties of Si3N4 have made it attractive alternative in the biomedical field also [2]. Bearings made of ceramics have low wear properties that make them a suitable alternative for total hip arthroplasty (THA) and total knee arthroplasty (TKA). When compared to cobalt chrome (CoCr)-on-polyethylene (PE) articulations, ceramics offer drastic reductions in bearing wear rates. Alumina and zirconia ceramics are familiar with the orthopaedic field in total joints for several decades [3]. Currently, Si3N4 is applicable in the biomedical field for various applications like bearing forspine disc surgery and prosthetic hip and knee joints also been developed with Si3N4 [4,5]. Bal & Rahaman [6] covered scientific rationale for the use of Si3N4 in the orthopaedic application.

Hexagonal boron nitride (hBN) is solid situ lubricating material with biocompatibility [7-9]. Incorporating solid lubricant in Si3N4 can be considered for improving the tribological performance of Si3N4 by the formation of an oxide of hydrated layers (H3BO3 and BN(H2O)x) has a significant effect on the tribological performance of Si3N4-BN composites, reducing the wear coefficient. Carrapichano et al. [10] conducted sliding wear test on pin-on-disc tribometer for Si3N4-BN composite in a self-mated pair, with 10, 18 and 25% vol. of BN in Si3N4. They concluded that addition of Boron up to 10% improved tribological properties of Si3N4 and further addition affect to mechanical properties of Si3N4. Chen et al. [11] investigated sliding wear behaviour of the Si3N4-hBN composite with 0, 5, 10, 20 and 30 volume % of hBN in Si3N4 against Si3N4 using pinon- disc (PoD) tribometer. They reported that friction coefficient reduces up to 0.19 for 20% volume of hBN in Si3N4.

Materials and Methods

DOE-Taguchi methodology

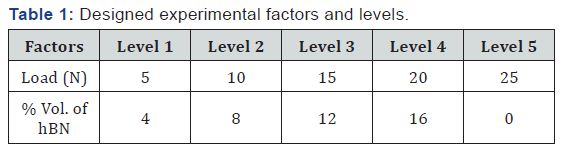

Taguchi method is a form of DOE developed by Genichi Taguchi used for planning experiments and to investigate how different parameters affect the mean and variance of a process performance characteristic [12]. Ferit et al. [13] analysed the wear behaviour of boronised AISI 1040 steel effectively using DOE-Taguchi design method. Amar et al. [14] implemented DOETaguchi design technique to evaluate the tribo-performance of polyesterhybrid composites. The result presented that glasspolyester composite without any filler suffers greater erosion loss than the hybrid composite with alumina filling. Lastly, the results were optimized using a genetic algorithm. Iihan & Suleyman [15] optimised turning parameters in CNC turning using Taguchi method and response surface analysis, presented efficiency and effectiveness of Taguchi method in the field of optimization. The experimental design proposed by Taguchi involves the use of orthogonal arrays to organize the control factors affecting the process and the levels at which they should be varied. It allows for the collection of the necessary data to determine which factors affect product quality significantly with a minimum number of experiments, saving time and resources. With knowledge of a number of parameters and the number of levels, the proper orthogonal array can be selected. The parameters /factors and their corresponding levels selected for the experiment as shown in Table 1.

Load and % volume of hBN are two factors chosen at five levels as shown in Table 1. Therefore L25(levelfactor= 52) orthogonal array selected using Minitab 17 software for conduction of experiment. The orthogonal array provides a set of well-planned experiment with the minimum number.

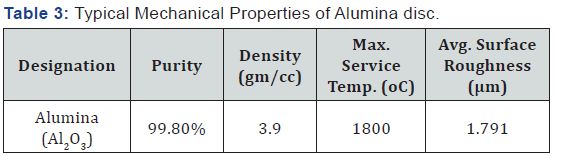

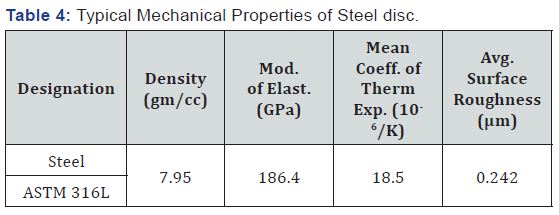

Preparation of samples

Si3N4-hBN composites prepared with 4, 8, 12 and 16% volume of hBN mixed in Si3N4. The mixing of Si3N4 and hBN is performed with a ball mill. The pin samples were prepared at uni-axial hot-pressing at 30MPa, 1600 °C and 60min dwell time with dimensions of 10mm diameter and 15mm long. Table 2-4 shows the properties of sintered specimens, properties of alumina disc and steel disc respectively.

*Testing at Central Glass and Ceramic Research Institute, Kolkata (India)

Experimental setup

The wear tests were conducted on Ducom TRLE-PMH400 pin on disc tribo meter having a maximum normal load capacity of 200N. Tests were performed according to ASTM F732 standards [16]. During wear test composite used as pin specimen against alumina disc and steel disc as counter face rotating at a speed of 200rpm (each test conducted for two times). Tests were performed at room temperature in a dry environment without lubricant condition.

Results

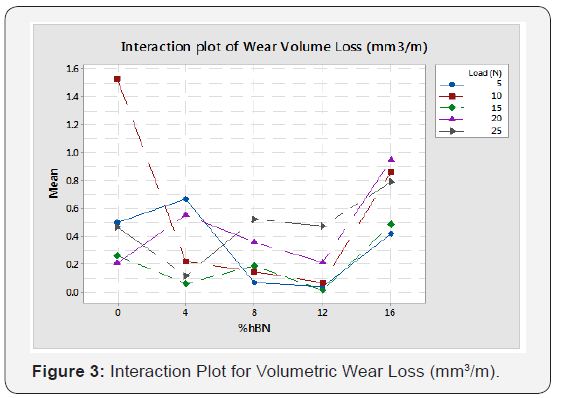

Signal-to-Noise (S/N) ratio analysis

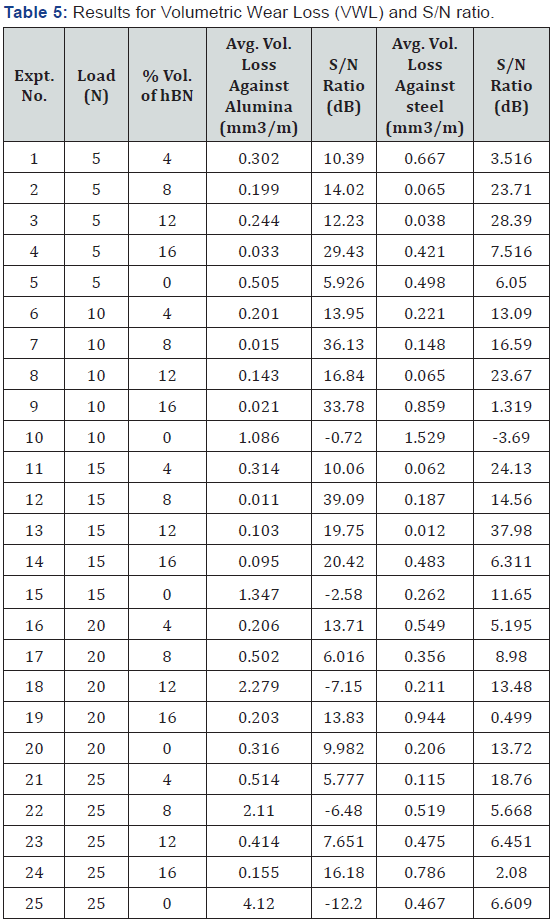

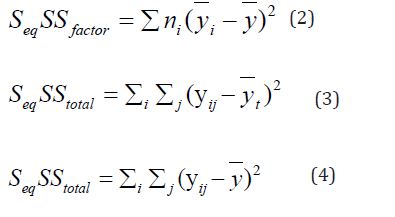

Experiments were carried out on Pin-on-Disc tribo meter with two input parameters and wear volume loss of a sample asoutput. Wear volume loss calculated for sliding distance covered by pin during 20min duration and speed of disc 200rpm at corresponding wear track diameter. Table 5 shows the average value of volumetric wear loss (VWL) for all 25 experiments (each experiment conducted two times). The experimental results are further transformed into Signal-to-Noise (S/N) ratio. Taguchi’s S/N ratios, which are logarithmic, the function of desired output and serves as an objective function for optimization. The standard S/N ratios used are: Smaller is Better (SB), Nominal is Better (NB), and Higher is Better (HB). The significance of controllable factor is investigated using S/N ratio approach. A smaller of wear volume loss is expected to extend joint life. Therefore in this study S/N ratio with Smaller the Better methodology was used for wear volume loss and calculated as follow:

Where,

y1, y2 and so on = Experimental results/observation.

n= Number of experiments (i……… n).

Irrespective of the category of the performance characteristic, the higher value of S/N ratio corresponds to a better performance [17]. The maximization of S/N ratio signifies maximization of the desired effect against noise factor. In this study minimization of wear volume loss is a desirable characteristic. Observation of response table of S/N ratio gives an optimal combination of input parameters for required output characteristic.

Response plot

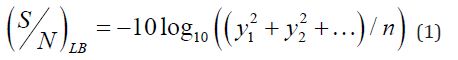

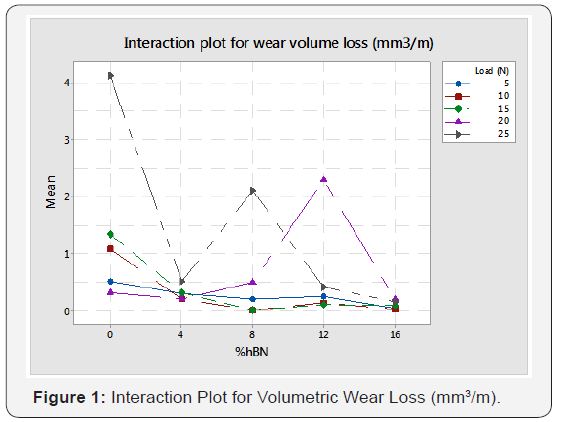

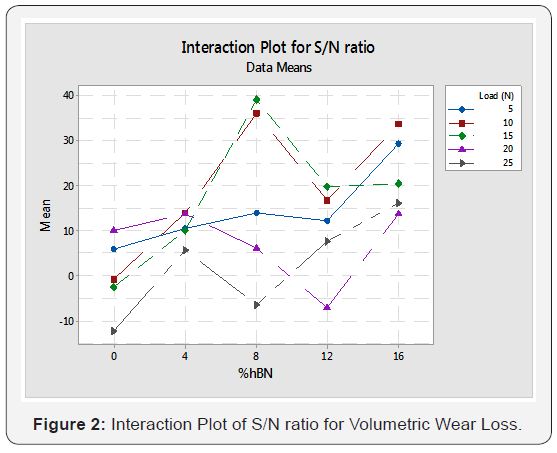

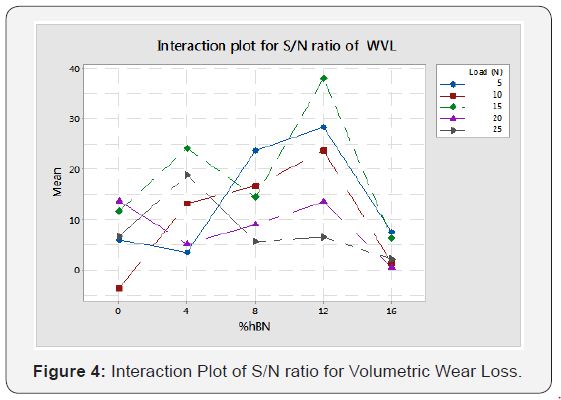

Interaction plot represents interaction effect of control factors: load and % volume of hBN on performance characteristic i.e. Volumetric wear loss.

Wear performance of composite against alumina: Figure 1 shows the minimum value of VWL at the interaction of 15N load and 8% volume of hBN and the maximum value of S/N ratio at same combination in Figure 2.

Wear performance of composite against steel: Figure 3 shows the minimum value of VWL at the interaction of 15N load and 12% volume of hBN and the maximum value of S/N ratio at same combination in Figure 4.

Analysis of variance (ANOVA)

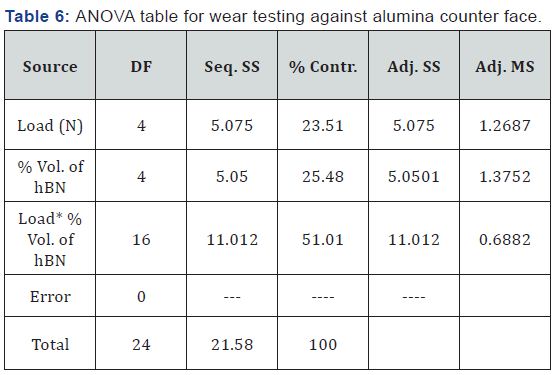

ANOVA is statistically based, objective decision- making a tool for detecting any difference in average performance of groups of items tested. It was developed by Sir Ronald Fisher in the 1930’s as a way to interpret the results from agricultural experiments [18]. ANOVA is a statistical technique which breaks total variation down into accountable sources; total variation is decomposed into its appropriate components. This technique determines the variability (variance) in data rather than analysis of data. Table 6 & 7 presents ANOVA table for wear testing against alumina counter face and steel counter face respectively.

In ANOVA table [19]:

The degree of freedom (DF) is a measure of amount independent information available from given set of data. DF for concerning factor is one less than the number of levels.

The sequential or adjusted sum of squares (Seq SS/Adj SS) of factor measures the variability in data contributed by that factor. Total SS is SS of an individual factor and SS of error.

Where mean of all observations at ith factor level, mean of all observations, yij value of jth observation at the ith factor level, ni number of observations for the ith factor level.

Wear performance of composite against alumina: from ANOVA table 51.01% contribution is due to combined effect of load and % volume of hBN while alone % volume of hBN has 25.48% contribution to wear performance.

Wear performance of composite against steel: from ANOVA table 51.89% contribution is due to combined effect of load and % volume of hBN while alone% volume of hBN has 35.04% contribution to wear performance.

Conclusion

From the study undertaken on the influence of load and % volume of hBN addition on the room temperature wearperformance of silicon nitride against alumina and steel, the following conclusions can be drawn:.

- The hBN addition has a significant effect on the wear rate of silicon nitride sliding against alumina as well as steel also.

- 15N load and 8% volume ofhBN volume of hBN in Si3N4 is the optimum combination to minimize wear rate of Si3N4 against alumina counter face.

- 15N and 12% volume ofhBN in Si3N4 is the optimum combination to minimize wear rate of Si3N4 against steel counter face.

- ANOVA result shows that interaction of load and % volume of hBN in Si3N4 has a significant effect on wear rate followed by % volume of hBN.

- Si3N4-hBN has proposed an alternative for hip/knee joint replacement, from experimental analysis it is clear that suitable combination of load and hBN addition should be considered for replacement of joint.

Boron Nitride Composite using Taguchi Method

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com/

for more details click on the juniper publishers material scienc

Comments

Post a Comment